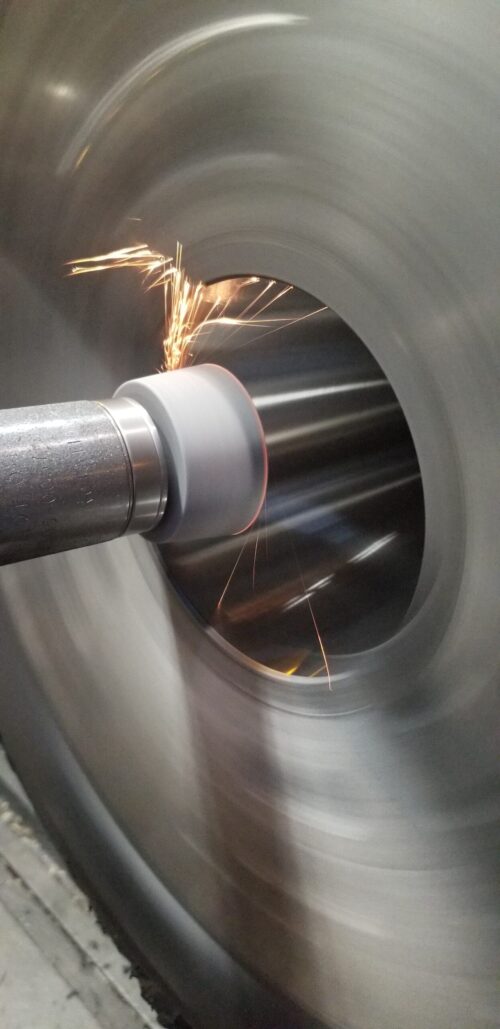

Spindle taper wear occurs on every machine tool over time. You will typically see a break down around the front of the spindle taper called “bellmouthing”. This condition will accelerate taper wear and may lead to runout issues, tool chatter, and poor surface finishes. Grinding the spindle taper in place, on the machine, can remedy all these issues with the shortest amount of downtime possible. In one shift, the machine can go from not operational to meeting new OEM specs.

Even after having a crash and spinning a tool, the taper can almost always be reground in-place instead of replacing the spindle saving you thousands or even tens of thousands of dollars. The damage and weld you see when a tool spins looks terrible but it is usually material build up from the tool holder and not actual damage to the spindle. In most cases, this can be ground away and the taper resurfaced.

We are also capable of grinding spindle using Big Plus and other Dual Contact tooling. As you remove material from the spindle taper, the tool will drop farther back. Dual contact tools require a specific dimension be held in order for it to seat on the taper as well as the face of the spindle. We can grind the spindle face to hold this dimension for machine tools using both bolt in style keys and integrated (part of the spindle) keys.

Recent Comments