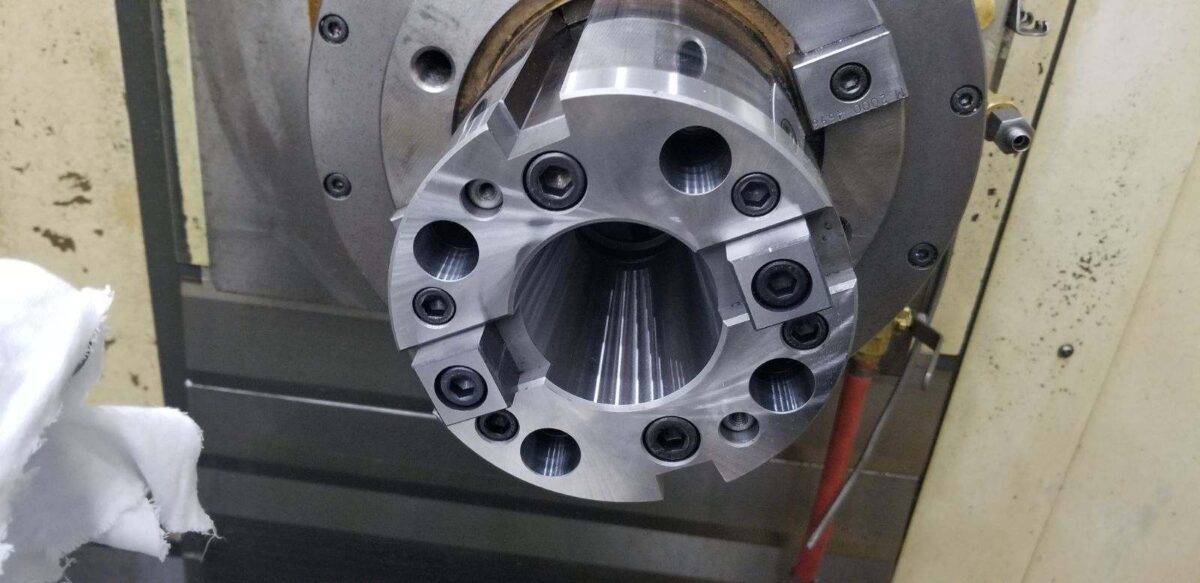

Replace the existing taper in your boring mill spindle bar with a Locher Insert.

Easily swappable on-site, regrindable, cut machine down time to less than one hour.Boring Mill Inserts

The Locher Spindle Tapered Inserts are a replaceable component that enable you to install a brand new taper into your machine with almost no down time. They are designed and manufactured by Locher, Inc and are compatible with machines with or without a tool changer. The inserts can be designed to utilize both standard CAT/BT tooling and Big Plus simultaneous fit. Typically after a crash with a machine, that machine will remain down until we can come in to regrind the taper. The insert allows you the option of pulling and replacing it after a crash reducing machine downtime to an hour from days or even weeks if the wreck is severe enough. A damaged unit can be sent in to be reground and placed back on the shelf. A machine can be converted over to an inserted design ON SITE in 4-5 days, eliminating the need to remove the bar and keep the machine down for an extended period of time. We have customers that have the inserts installed into every boring mill due to its advantages over solid tapers. We recommend that a damaged insert be reground in-place as needed and replaced only after regrinding is not possible. The close fit between the insert and bar can be damaged causing runout. Caution must be used when replacing the insert. Call us today at 800-956-2437 for a no cost consultation. Call us today at 800-956-2437 for a no cost consultation.

Request a Free Quote

At Locher, Inc. we provide our customers with complete spindle rebuilding, in-place spindle taper regrinding, tapered insert retrofits and bar & sleeve repairs - performed either in our factory or yours. Contact us for a free quote.