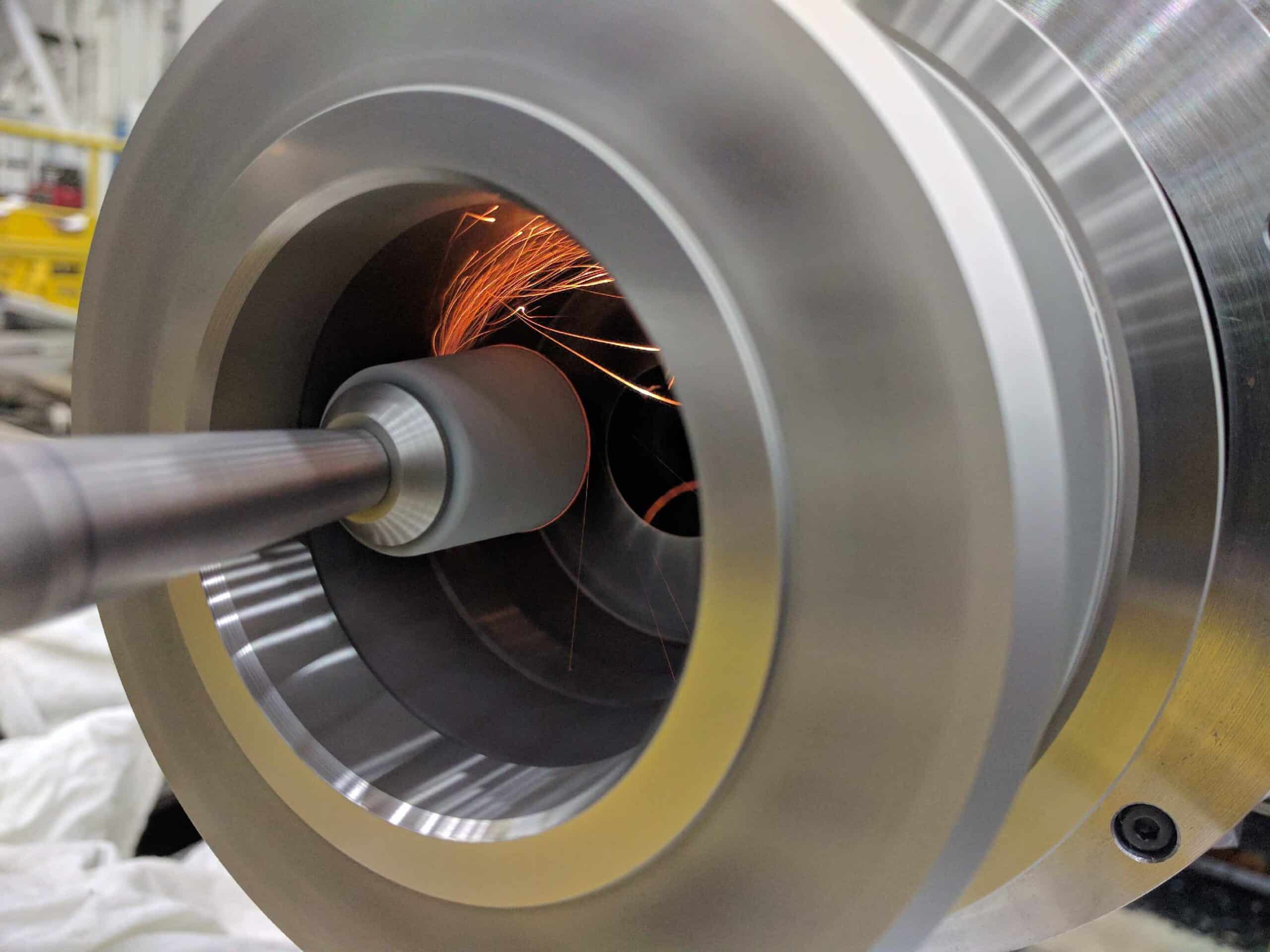

Spindle taper grinding is your solution to poor part finishes, tool chatter, and runout.

Don't just replace the spindle. Regrinding the spindle taper can remedy many of these problems and bring runout back to factory new specs.On-Site Spindle Taper Grinding

On site spindle taper grinding is one of the most overlooked maintenance services in the plant. Over time, spindle taper wear will occur on any machine which can lead to problems with runout and part finishes. Tools can spin and cause damage after a retention knob breaks, an operator oversight or programming error causes a wreck, or a part comes loose on the table. This damage is almost always repairable in place, within one shift, without needing to pull or rebuild the spindle. With the rise in spindle replacement costs, this should always be the first choice in spindle repair.

Outfitted with mobile grinding units, our experienced field service technicians can come on-site, anywhere in the country, set up on your machine, and grind the damaged spindle taper back to new specifications. This reduces your machines downtime from weeks to days. You will receive a full inspection report including taper contact, clamping pressure, and test bar runout. Big plus or dual contact tooling is not a problem.

Remedy issues like

- Poor tool or spindle taper runout

- Tools sticking in the taper

- Tool chatter

- Poor part finishes

- Spun tool and galling in the taper

Contact Locher, Inc. today for more information at 800-956-2437.

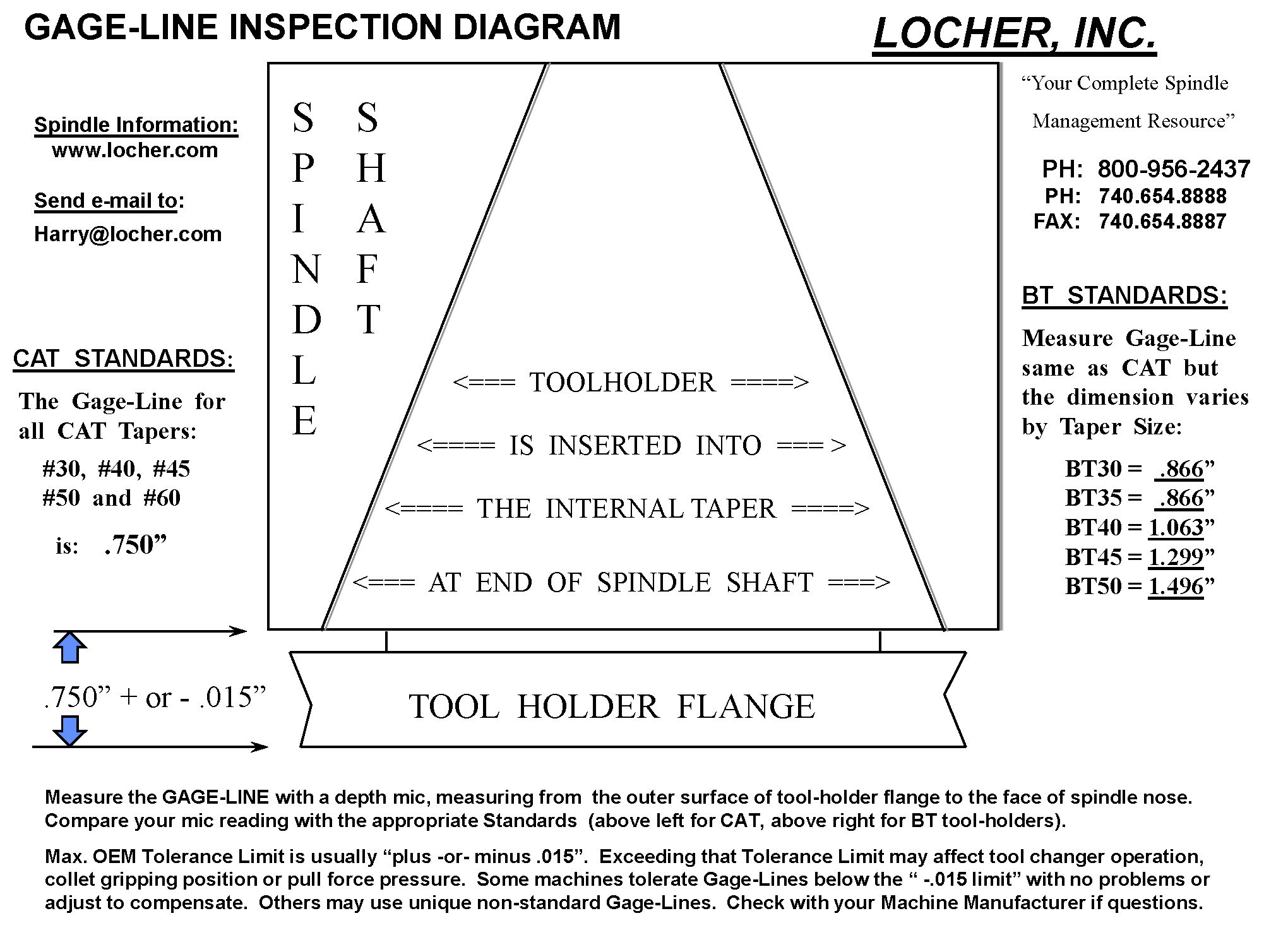

We can grind any spindle taper on site

- CAT 30, 40, 45, 50, or 60 spindle taper grinding

- BT 30, 40, 45, or 50 spindle taper grinding

- Big Plus BBT machines

- Ingersoll Simul-fit spindle taper grinding

- Morse tapers

- Lathe Chuck OD or ID tapers

The Advantage of On Site Spindle Taper Grinding

Spindle taper wear occurs on every machine tool over time. You will typically see a break down around the front of the spindle taper called “bellmouthing”. This condition will accelerate taper wear and may lead to runout issues, tool chatter, and poor surface...

Request a Free Quote

At Locher, Inc. we provide our customers with complete spindle rebuilding, in-place spindle taper regrinding, tapered insert retrofits and bar & sleeve repairs - performed either in our factory or yours. Contact us for a free quote.